Business model

Turning sustainability into our competitive edge

Providing the best technological solutions for clean mobility and recycling.

Metals

Metals are an outstanding ingredient for sustainable materials production because they can be recycled infinitely without losing any of their chemical or physical properties. This is one of the foundations of our business model. A high volume of our metals come from recycled sources - production scraps and residues from customers and other industries, and end-of-life materials through our closed-loop services. Using our Sustainable Procurement Charter and our framework for Cobalt, we purchase the remainder of our metal supplies from sustainably and ethically vetted primary sources.

Application know-how

We take metal and apply our expertise in metallurgy, chemistry, engineering and materials science skills, we add our product, process and market know-how and offer solutions that enable our customers to develop better, more sophisticated and safer products.

Material solutions

Our know-how transforms metals into functional materials that are integrated into products by our customers, usually companies making products for consumer or industrial use. Our catalysis materials provide clean air and health solutions, while our battery materials give added range and performance to electric vehicles and increased battery life to portable electronics. Our materials are also inside computer motherboards, in domestic light switches and in the fiber optics and satellites that keep you connected.

We transform metals into functional materials and recycle them to make new materials. Our products deliver solutions for cleaner air and increased e-mobility, while we turn wastemetals into a resource. Our ethical sourcing and closed-loop approach give us a greater competitive edge.

Recycling

We run two types of recycling operations that, together, can recover 28 metals. Our precious metals recycling operation in Hoboken, Belgium, is built to recycle and refine the most complex materials and to recover a broad spectrum of metals. Our other recycling operations, in collaboration with customers, recover specific metals from production residues.

Many factors – from raw materials supply to talent retention – underpin our business model. We manage these resources and relationships for the long term.

Skills and expertise

Our colleagues contribute to Umicore through their expertise and commitment. Metallurgy, chemistry, engineering and materials science skills are critically important in our key growth areas: recycling and materials for clean mobility.

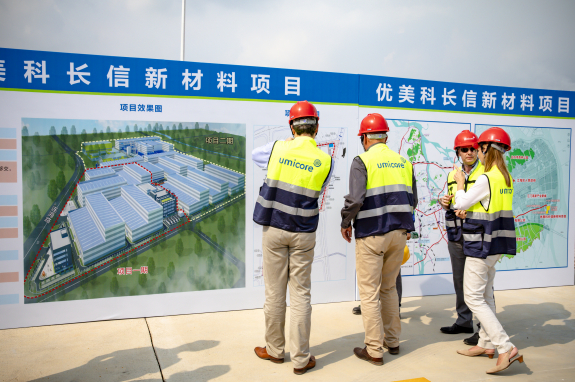

We are growing in Asia and in Europe and this means a greater focus on attracting talent for positions ranging from production operators, engineers, research scientists, to commercial and administrative functions.

Umicore technology

Technology is at the core of our success. We are committed to innovation and research and development (R&D) are key for innovation-led growth. We develop a significant part of our technology using Umicore R&D findings and invest 6% of our revenues in R&D. Umicore also develops technology in with our industrial or academic partners and we protect our intellectual property with patents.

Umicore operations

Our operations are carried out in recycling plants, specialised chemicals and materials production facilities, offices and research centers, in 30 countries, often close to our customers to support collaboration and to meet their specific product requirements. We aim for excellence in environmental and social performance in all our operations.

We seek to minimise the impact of metal emissions, generate improved material and energy efficiency and offer a safe and healthy workplace. Operational excellence is important both in securing our license to operate and in helping to make Umicore more competitive.

Maximum efficiency from energy & auxiliary materials

Input materials such as fuels and chemicals are essential to Umicore operations and are purchased using our Sustainable Procurement Charter framework. In most of the countries where we operate and given the specific nature of many of our operations, there is limited choice in terms of energy sourcing. For this reason, our priority is to maximise energy and auxiliary materials efficiency.

Investment and funding

Investing in Umicore is an investment in producing materials for a better life – our mission – and supporting our strategy. Umicore has a proven track record of funding strategic growth initiatives from the capital generated from our own operations. Indebtedness is kept low, as we aim to retain the equivalent of an investment grade credit status.

Our closed-loop business model delivers economic, social and environmental value for all our stakeholders.

Products & Services

Our ambition is to produce materials for a better life. Umicore products can be found in applications that make day-to-day life more comfortable and contribute to a cleaner, more efficient world. We work closely with our customers to develop customized materials or processes that consider health and safety, recyclability, cost efficiency, waste reduction and energy efficiency both in our own facilities and in the value chain. We continuously search for innovative solutions for our customers and work to meet the needs of a rapidly changing and more demanding world.

The Umicore Way

Umicore is committed to the principles of sustainable development. We aim for excellence in environmental and social impact and strive to offer a safe and healthy workplace. We offer solutions to global challenges: our recycling services address growing resource scarcity and reduce industrial waste and emissions. Our catalysts help reduce air pollution, while our rechargeable battery materials help make electrified transportation a reality. Umicore offers high quality employment with competitive salaries, training and development opportunities and longterm employment prospects.

Each site aims to be considered as a preferred employer locally. Umicore supports the principle of collective bargaining and signed a Global Framework Agreement on Sustainable Development with the IndustriALL Global Union.

Superior Growth and Returns

Umicore aims to generate a return on capital employed of more than 15%. One of our Horizon 2020 goals is to double our earnings, mainly through growth in recycling and materials for clean mobility. While the primary focus is on organic growth, acquisitions are also considered if they fit the strategy and can add value for shareholders. Umicore pays out a stable or gradually increasing dividend and has a track record of returning excess cash to shareholders through share buybacks.